R&D Whitepaper: Recycling of Oversize Additive Manufacturing Powders

Oct 28,2024

Authors: Aamir Abid, Matt Stone, Geof Dusky, Bryce D’Alba

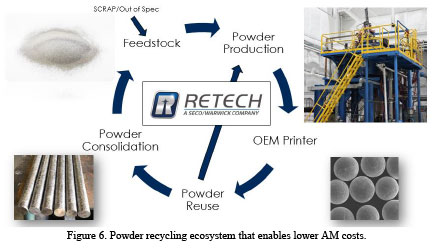

Abstract: The demand for additive manufacturing powders is expected to grow over the next several years as the technology scales to production. In order to achieve broad adoption of AM, the overall production costs need to continue to decrease. The powder costs are a significant input to the overall cost for AM and an active area of research and development in the industry. Gas atomization is one of the processes by which high-value AM powders are produced on an industrial scale. Only a fraction of the powder distribution produced by this process is utilized by AM. For example, for laser powder bed fusion (LPBF) modality, the typical usable powder size range is between 15 – 63 um. The as-produced powder distribution via gas atomization is broader and results in the production of oversize powder that is not utilized for AM processes. There is an urgent need to develop solutions for recycling oversized powder and reducing the overall cost of the AM feedstock. Retech has developed a powder consolidation system that recycles oversize powders into high-value ingots. The system is designed to feed a broad range of alloys including nickel, titanium, and other reactive and refractory powders. In this work, we describe the performance of the powder consolidator, and the characteristics of the ingots produced from powder.

Click to read the R&D Whitepaper.

Talk to an Expert About Developing Your Powder Metal Production Process.