R&D Whitepaper: Production Scale Plasma Atomizer for Reactive and Refractory Metal Alloys

Sep 27,2024

Authors: Aamir D. Abid, Matt Stone, Geof Dusky, Bryce D’Alba

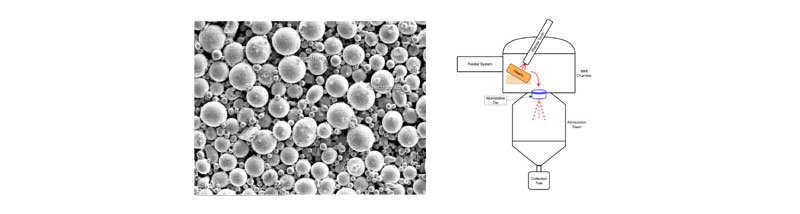

A barrier to broader adoption of refractory and reactive metal powders (like Titanium and its alloys) is centered on the combination of the net cost of production for specified powders and the availability of suitable capacity to address the demand. Additionally, though firms are producing similar powders using a range of technologies, not all available powders are compatible with current additive manufacturing systems nor have all the potential alloys been available in powder form to be applied to any particular application. With that in mind, Retech has undertaken a focused effort to develop an atomization system that would provide a larger production capacity of a range of metal and alloy powders utilizing Plasma Arc Melting (PAM) in combination with gas atomization. Plasma melting allows for the introduction of a broad range of feed materials including revert without incurring the additional cost of processing feed to wire or bar forms. With this flexibility of feed materials, recycling high-value materials has become an economically viable option. The powders produced on the Plasma Atomizer are spherical with minimal satelliting and low internal porosity. Powder Particle Size Distribution (PSD), morphology, and chemistry will be presented in this study and these results will be compared to the current state-of-the-art commercial atomized powder technologies. Read Full Article

Talk To An Expert About Developing Your Powder Metal Production Process