Spark Plasma Sintering (SPS)

Spark Plasma Sintering (SPS)

GeniCore U-FAST (SPS) CompactGeniCore U-FAST (SPS) GC

GeniCore U-FAST (SPS) Hybrid

GeniCore U-FAST (SPS) MASS

Retech has teamed up with GeniCore to represent their Spark Plasma Sintering (SPS) technology in the North American market. Spark Plasma Sintering (SPS) technology, also called Field Assisted Sintering Technology (FAST), enables effective consolidation of pure metal powders, metal alloys, as well as ceramic and metal composites using pulsed direct current. The SPS process bonds materials using a combination of pressure and thermal energy applied to materials in a mold. It resembles Hot Pressing, but the SPS process consumes far less energy and, most importantly, can bond a broader range of materials into novel composites unachievable by other processes. The “spark” in spark plasma sintering is more of a powerful pulse of electric current that passes directly through the material in the mold form while it is under pressure. To withstand the heat and pressure, the molds are made of graphite, which is machined into a negative shape. As the material is compressed in the mold while under vacuum, a pulse of direct current is passed through the material, producing the high temperatures necessary for sinter bonding to occur. The current pulse heats the material via Joule heating rather than radiant, applying the heat only where needed, thereby using less energy than traditional hot pressing or sintering methods. GeniCore’s pioneering advancement in SPS/FAST technology is in their Direct Current (DC) electric pulse switching, enabling the most precise DC waveform control in the emerging SPS industry — controlling each pulse’s current, duration, and spacing -- hence the name Upgraded Field Assisted Sintering Technology (U-FAST). Generating pulses of under one millisecond, and even, precisely programmable square-pulse packets, delivers tremendous energy directly into the materials being consolidated. This precision pulse control, in turn, breeds the greatest precision in sintering, resulting in uniform consolidation with minimal grain growth. Process trials yield material compositions unachievable by any other processes. GeniCore U-FAST devices are available in the four different configurations listed below to accommodate varying applications, part sizes, production throughput, and budgets. Additionally, the modular design allows for any of the configurations to be upgraded to the next larger model.

GeniCore U-FAST (SPS) Compact

A Small, Powerful, Precise, and budget-friendly U-FAST solution to support innovation. U-FAST Compact offers the same quality performance but with lower initial investment and lighter infrastructure requirements.

Materials:

Transparent ceramics, sintered carbides, Bulk Metallic Glasses, Thermoelectrics, High-Entropy Alloys, Super Enhanced Ceramic Whiskers (SEC-W), Ballistic Plates , Composite tooling, High thermal-conductivity substrates.

Applications:

Producing small parts for R&D, trial batches.

GeniCore U-FAST (SPS) GC

The GeniCore U-FAST GC model is a perfect fit for R&D scale and small batch production needs. It is designed for tech enterprises with R&D departments and manufacturing businesses developing and experimenting with new materials prior to scaling up to full scale production volumes.

Materials:

Transparent ceramics, sintered carbides, Bulk Metallic Glasses, Thermoelectrics, High-Entropy Alloys, Super Enhanced Ceramic Whiskers (SEC-W), Ballistic Plates , Composite tooling, High thermal-conductivity substrates.

Applications:

R&D, Low-Volume Production

GeniCore U-FAST (SPS) Hybrid

GeniCore’s U-FAST Hybrid pairs SPS technology with induction heating to achieve the same uniform material quality in larger parts than can be achieved by SPS alone. As part sizes increase, current density becomes more irregular. The irregular current density can be compensated for using induction heating, extending U-FAST part size up to 200mm. The independently controlled induction heating also shortens cycle time to achieve higher production throughput.

Materials:

Transparent ceramics, sintered carbides, Bulk Metallic Glasses, Thermoelectrics, High-Entropy Alloys, Super Enhanced Ceramic Whiskers (SEC-W), Ballistic Plates , Composite tooling, High thermal-conductivity substrates.

Applications:

Capable of producing larger parts, up to 200mm diameter. High production throughput.

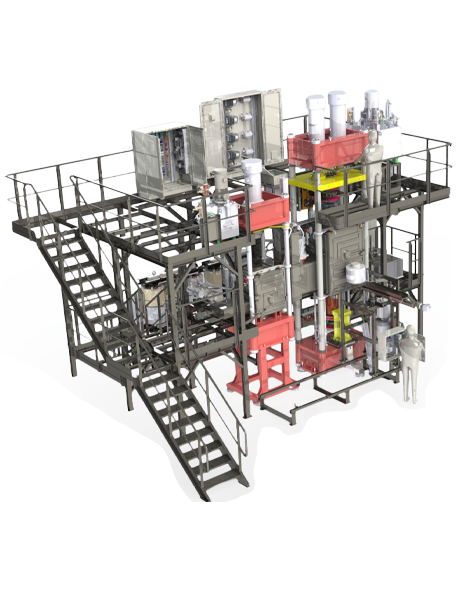

GeniCore U-FAST (SPS) MASS

U-FAST MASS stands at the forefront of sintering technology, particularly as an automatic sintering machine ideal for large-scale production. Designed for industries seeking efficiency, precision, and scalability. U-FAST MASS not only continues to push the boundaries in the world of SPS systems but also heralds a new era in advanced composite material manufacturing.

Materials:

Transparent ceramics, sintered carbides, Bulk Metallic Glasses, Thermoelectrics, High-Entropy Alloys, Super Enhanced Ceramic Whiskers (SEC-W), Ballistic Plates , Composite tooling, High thermal-conductivity substrates.

Applications:

Fully Automated Large-scale Continuous Production